Choisissez un autre pays ou une autre région pour voir le contenu spécifique à votre emplacement

Current region:

Global (EN)

Global (EN)

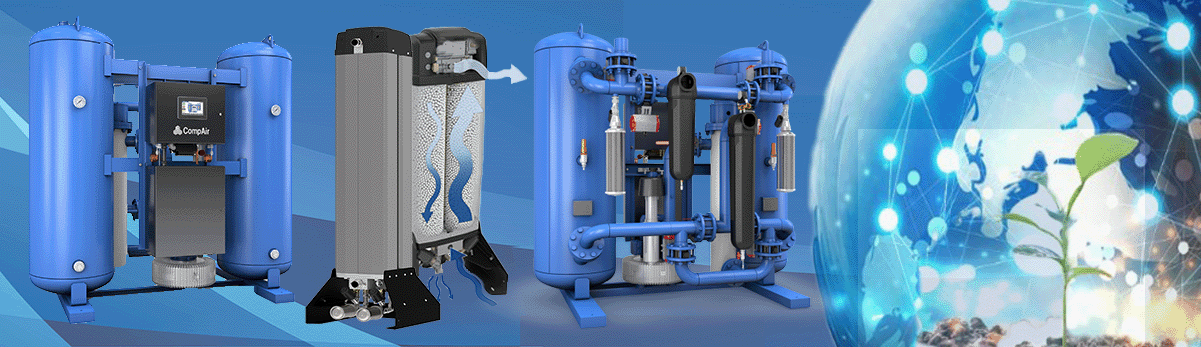

Dry compressed air has become essential in many industries to maintain the reliability of production processes and to ensure the highest quality of your products. Air not treated by an adsorption dryer can lead to corrosion of the pipes and premature failure of the system.

The humid air passes through a compound that is called desiccant, meaning moisture absorber. Once this is saturated with water, it is necessary to dry this desiccant.

The column containing the moisture absorber is depressurized and the accumulated water is drained. After this operation the regeneration method depends on the type of adsorption dryer.

There are two techniques:

Each of these products has advantages and disadvantages that must be known to ensure the best effectiveness.

The special feature of a heatless adsorption dryer is that a part of the dried compressed air stream is taken and used for regeneration purposes, which considerably reduces the compressed air loss and the operating costs.

In the context of an adsorption dryer with regeneration by heat input operating according to the dynamic adsorption principle. As with any adsorption dryer the wet compressed air flows through a desiccant bed. The moisture is then retained.

In this context, the use of two parallel adsorption columns with alternating functions guarantees a permanent supply of dry air. An adsorber is always available to dry the compressed air. The second adsorber is regenerated at the same time.

Superior reliability

Adsorption dryers have the ability to remove moisture from compressed air at a pressure dew point of up to -40°C/-40°F. This prevents the formation of condensation and protects your machines.

A formidable efficiency

In this type of dryer, the adapted size of the pipes and valves guarantees a limited pressure drop.This system allows to increase the efficiency of the system while reducing the energy consumption, different options are available.

Low maintenance

The dryers we offer have a limited footprint thanks to their "all-in-one" design. Delivered ready to use, they are quick to install to minimize production downtime. All internal components are easily accessible for easy maintenance. An interval of three years is the minimum between each maintenance.

The adsorption dryer DRYPOINTAC 119 - AC 196 with regeneration without heat input guarantees a stable supply of high quality compressed air for flow rates between 10 and 120 m³/h using a high performance adsorbent. The adsorbent in cartridges retains the moisture contained in the compressed air up to a pressure dew point of -70°C.

The adsorption dryers of the series DRYPOINT AC 410-495 and the DRYPOINT HL guarantee a stable supply of high-quality compressed air by using high-quality adsorbent. The adsorbent removes moisture from the compressed air up to a pressure dew point of -40 °C, optionally up to -70 °C. This guarantees an economical production without any difficulties.